This product has been discontinued and removed from our shelves.

Features

1. The overbridge conveyor falls into single-layer, double-layer and three-layer types in accordance with the number of layers of the corrugated cardboard production line. It works for transmitting and rectification of the cardboard.

2. The lifter adopts synchronous motor drive and PLC control to keep pace with the single face corrugator.

3. The conveying equipment is equipped with a rectification and tension machine with adjustable absorption and tension forces. The suction tension device uses the high voltage centrifugal variable frequency motor for vacuum absorption and tension of the cardboard, as well as electrical rectification of the deflected cardboard so as to make the cardboard affixed firmly and flat. Additionally, the deflected cardboard can be corrected on or off the overbridge conveyor.

4. The overbridge frame of the product is assembled with safety guards and lifting ladders.

5. The single-faced corrugated cardboard fabricated by the single facer is accurately transported to the tension brake or the suction brake with the conveying belt for the overbridge conveying device in the next processing procedure.

6. Two groups of operation boards are installed for electrical control and can be regulated on or off the overbridge conveyor.

7. The paper collecting section makes use of an independent variable frequency drive for synchronization with the single facer. The single faced corrugated cardboard manufactured from each single facer is transmitted onto the overbridge conveying unit and reserved in a certain quantity so as to cope with the changing speed of the production line. Ultimately, the corrugated cardboard is conveyed to the multistage preheater for heating. Then, it is delivered to the Corrugated Cardboard Glue Coating Machine and double facer for gluing and shaping.

8. The overbridge conveyor comes with the paper feeding stand with two groups of tilted conveying belts. The conveying and stacking speeds are relatively low for formation of wavelike overlapping. Thus, corrugated cardboard made by the single facer can be stored.

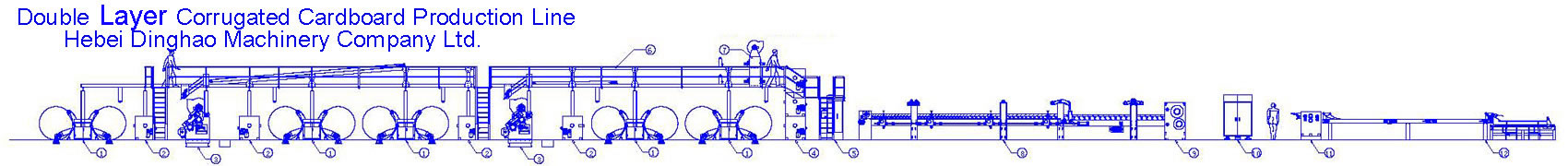

9. The location of the overbridge conveying device in the WJ computer high speed corrugated cardboard production line is shown in diagram ⑥ ⑦ ⑤.

Structure Drawing of WJ Computer High Speed Corrugated Cardboard Production Line

1. Mill Roll Stand

2. Corrugated Cardboard Preheater

3. Single Facer

4. Corrugated Cardboard Glue Coating Machine

5. Escalator

6. Corrugated Cardboard Conveyor

7. Rectification and Tension Machine

8. Drying and Shaping System

9. Main Driving System

10. Corrugated Cardboard Slitter Scorer

11. Corrugated Cardboard Cutting Machine

12. Stacker