The raw paper roll is used for recombination with multi line widths for choice. Any including 2-layer, 3-layer, 4-layer, 5-layer and other multi-layer paper can be recombined with paper gram weight 1200g-2000g/SQM, thickness 3.5mm and production capacity 35-80T/Day available. Its finished cardboard can be comparable with kinds of international products on thickness, tightness, moisture, evenness, stiffness and tensile strength, instead of imported super thick hardboard, used for cigarette, wine, luggage, food, hard book cover, high end gift box and stationery packaging.

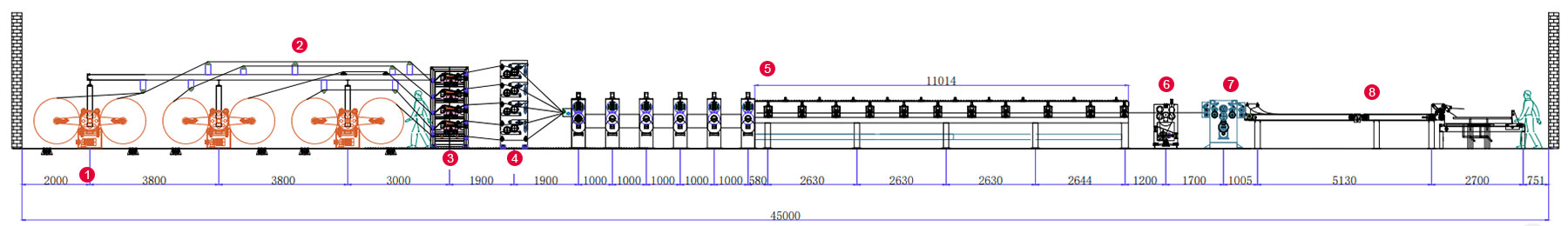

Our company successfully searched and developed the industrial cardboard (hardboard) recombination production line of domestic advanced technology with years of sheet machinery making experiences. It makes up lots of defects from manual mounting of single machine for low production cost, high production capacity and considerable economy benefit. It is featured by advanced procedures, simple operations and maintenance, safe and reliable capacity and resource saving without pollution in sheet production, which makes your ideal equipment in industrial cardboard (hardboard) manufacturing. It is mainly composed of mill roll stand, rails & trolley, multi-layer transmitting machine, pasting machine, pressing machine, drying part, cooling part, puller, slitting machine, NC cut off and stacker.