The automatic glue making machine is developed for manufacturing glue for corrugated cardboard.

Configurations

1. Material Mixing System

The material mixing system for the automatic glue making machine contains specially designed stainless steel reaction tank processed with surface treatment technology. The 1.5kW mixing motor, as well as the vertical mixing system, is conducive to the optimal mixing effect. In addition, the three sets of independent high precision weighing system help user control the amount of the raw material easily.

2. Stand and Platform

The stand is produced from standard Q235-A carbon steel, and the platform for the glue making system is made of riffled plate. In addition, the platform for the automatic glue making machine is installed with guardrail and ladder manufactured from Q235 carbon steel.

3. Control System/Software

This adhesive machinery comes with 1 set of main control cabinet. All the motors are installed with failure protection and system failure alarming system. Our product employs Siemens PLC, Taiwan WEINVIEW (or other brand required by the client) human-machine interface, as well as the homemade pneumatic element. The specially designed software enables users to grasp the operation skill in a short time. The multistage password protection for formula and parameter alteration ensures high safety of the automatic glue making machine.

4. Auto Borax and Additive Feeding System

We particularly design the storage tank with anti-blocking device to avoid feeding failure caused by moist borax. The 3 sets of independent high precision weighing system can effectively control the dosage of the borax and additive.

5. Auto Alkali Liquor Feeding System

The automatic alkali liquor feeding system of the automatic glue making machine is composed of stainless steel storage tank and diaphragm pump with good durability imported from American GRACO.

6. Automatic Steam Feeding System

Our automatic steam feeding system consists of 1 set of temperature control system and the pneumatic ball valve to control the feeding of steam. In addition, the steam feeding system has the function of alarming if abnormal heating is detected.

7. Auto Water Feeding System of Automatic Glue Making Machine

The water source can be tap water, recycled water (from equipment cleaning), or the mixture of the said water source. The supply of clear water and the recycled water can be switched automatically to avoid shortage of recycled water.

8. Automatic Glue Delivery System

The 2 inch pneumatic diaphragm pump made of cast iron is imported from other country. Working together with the storage tank control system, the diaphragm pump helps deliver the glue to the specific storage tank for the single facer or the double facer, automatically. Moreover, our glue production line is engineered with level sensor to detect the storage condition of the liquid in each tank. In case the glue in the storage tank is less than the preset value, the level sensor will send signal to the automatic glue making machine for automatic starting.

9. Starch Storage Tank, Starch Conveying System, and Raw Material Delivering System

The 1.8 ton starch storage tank and the conveyor are responsible for delivering the starch to the reaction tank. The starch storage tank is installed with anti-blocking device and liquid level sensor, as well.

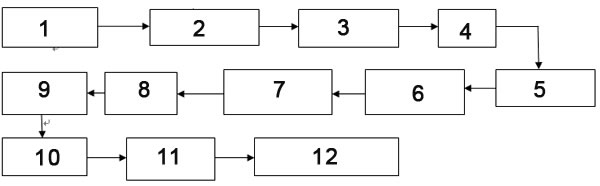

1.Water

2.Initial temperature, mixing

3. Starch

4. Alkali liquor

5. First mixing

6. Water

7. Secondary heating

8. Starch

9. Additive

10. Borax

11. Secondary mixing

12. Glue delivery to the storage tank

| Item | Specifications | Quantity |

| Main Motor for Mixing | 3-phase 380V 15kW | 1 |

| Motor for Starch Conveyor | 3-phase 380V 4kW | 2 |

| Motor for Starch Curing Agent Conveyor | 3-phase 380V 0.55kW | 1 |

| Motor for Stabilizing Agent Conveyor | 3-phase 380V 0.55kW | 1 |

| Motor for Borax Conveyor | 3-phase 380V 0.55kW | 1 |

| Motor for Sodium Silicate Mixing | 3-phase 380V 0.40kW | 1 |

| Machine Size | 4000×2000×3200 (mm) (Model 1800) |

| Installation Dimension: | 8500×3000×3500 (mm) (Model 1800) |

| Power Supply | Standard 380V±10%, 50Hz, 3-phase |

| Glue Making Capacity | Max. 1500kg, min.: 500kg |

| Mixing Mode | 15kW motor plus double-layer mixing impeller |

| Alkali Liquor Conveying Mode | 1/2" pneumatic diaphragm pump |

| Glue Conveying Mode | 2" pneumatic diaphragm pump |

| Heating Mode | Steam |

| Operation Interface | Touch screen human-machine interface |

| Weight Control | Reaction tank: 3 weighing sensor Auxiliary material tank: 3 weighing sensor |

| Control System | PLC, human-machine interface, and control panel |

| Software | Humanized operation control system exclusively developed by ARIMA, supporting direct formula input, switch between automatic and manual control, and automatic inspection |

| Mixing Motor | 3-phase AC motor |

| Storage Tank | 1 tank for starch and auxiliary material (borax and additive), respectively |

| Level Sensor for Starch Storage Tank | 2 pieces |

| Alarming System | The alarm will be sent out in case material feeding motor failure, material overfilling and material shortage, or valve on-off failure is detected. |

| Item | Quantity |

| Viscosity Cup | 1 |

| Electronic Stopwatch | 1 |

| Electronic Thermometer for Gelatinization Point Testing | 1 |

| Beaker (250ml) | 1 |

| Thermal Resistance | 1 |

| Item | Brand and Model |

| Main Mixing Motor | Siemens 22/18.5/15kW |

| Motor for Material Conveying | 4kW |

| Pneumatic Element | AirTac |

| Pneumatic Valve | BESTONE |

| Diaphragm Pump | America GRACO |

| Weighing System | America MK |

| Human-Machine Interface | Taiwan WEINVIEW/Siemens/Schneider |

| PLC | Siemens |

| Flowmeter | Siemens |

As a professional supplier, we will offer overall services to bring more convenience to our client. It takes about 15 days for the completion of automatic glue making machine installation, debugging and personnel training.

1. We will discuss with our client about machine installation in advance (1 day).

2. Location confirmation, installation, piping, debugging and safety confirmation (7 days).

3. It will take about 7 days for glue formula adjustment, operator training, and simple failure handling.

Customers are welcomed to contact us for more details related to the technical parameters of the automatic glue making machine.