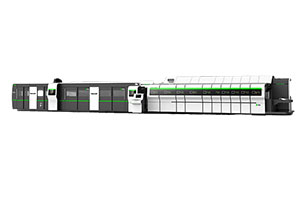

This corrugated cardboard machine is composed of feeding, printing, slotting, die-cutting, gluing and strapping units, which can finish 3-layer or 5-layer sheet printing, scoring, slotting, chamfering, punching, gluing and strapping at one time.

This machine is composed of feeding, printing, slotting, die-cutting and stacking units, which can finish 3-layer or 5-layer sheet printing, scoring, slotting and chamfering at one time.

The label printing machine is composed of unwinding and rewinding device with pneumatic shaft, printing unit, CCD camera, touch screen, secondary printing, web guide unit, auto ink adjusting device, Yaskawa or Panasonic servo motor, automatic oil supply system, and automatic 0.15mm plate installation and adjustment unit.

The printing and die cutting machine is specially designed for high speed, high accuracy, high efficiency, high reliability, and high safety.

The high speed water based ink printing slotting machine is devised and manufactured in line with high requirements and reliability. Owing to the user-friendly operation design, this product can easily carry out functions of setting, modification, performing, replacing and memorizing in a very short of time. Meanwhile, any change can be displayed with digits accurately.

The water based ink printing slotting machine comes with domestically famous electrical components. It is crosshead shoe driven, and spray lubricated in a circulating way. All the roller shafts are chrome plated and the planetary gear mechanism is used for phase adjustment. Additionally, the phase adjustment system comes with digital input and return-to-zero functions.

The high speed water ink printer slotter machine can be applied to common cartons or small-sized cartons, based on high effectiveness.

The whole product is driven by the cross-slide system for reducting gear adjustment error. The spray lubrication is beneficial for decreasing noise, thus prolonging the operation life of the whole unit.