This product has been discontinued and removed from our shelves.

The corrugated cardboard production line is critical production equipment for corrugated box manufacturers and plays and essential role in making corrugated boxes with the total layer number being three, five or seven. By contrast, foreign customers usually called three layer, five layer or seven layer corrugated boxes in accordance with the number of the fluted sheet.

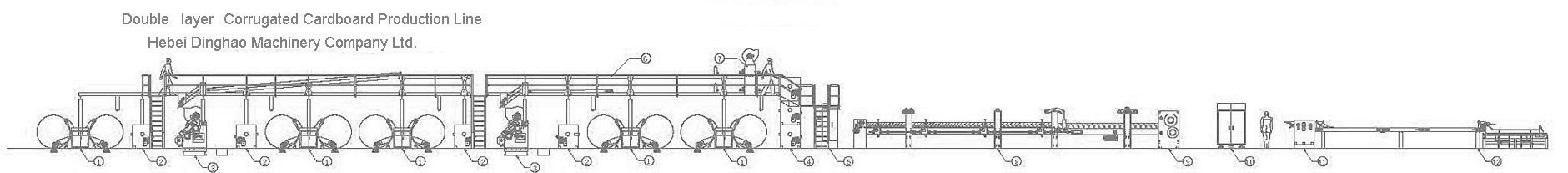

This corrugated cardboard production line consists of the paper mill roll stand, preheater, single facer, overbridge conveyor, multistage preheating device, Corrugated Cardboard Glue Coating Machine, bonding and drying equipment, cutting machine, slitting scorer machine, cross cutting machine, stacking unit, pulping system, electronic control system, etc.

Working Process

1. A roll of paper is conveyed into the paper mill roll stand and unfolded.

2. Then, the corrugated medium is heated by the preheater with the humidity being adjusted.

3. It enters into the single facer for further heating, corrugating and glue coating.

4. After a series of processing, the paper is pressed and bonded into single-sided corrugated cupboard.

5. Afterwards, such a corrugated cupboard is pulled to overbridge conveyor by the hoister of the production line.

6. After being stacked in a given order, it will be transported to multistage preheating device for a secondary heating.

7. The Corrugated Cardboard Glue Coating Machine of the corrugated cardboard production line is used to coat glue on the seams of different corrugated parts.

8. The glued corrugated cupboard together with the bottom paper will go into the bonding and drying machine, as well as will be compounded together into corrugated cardboard.

9. The corrugated cupboard will be cut into given specifications with the effects of slitter scorer and cross cutting machine adopted in the production line.

10. At last, the corrugated cupboard is orderly stacked by the stacking machine and then delivered out.