This product has been discontinued and removed from our shelves.

Features

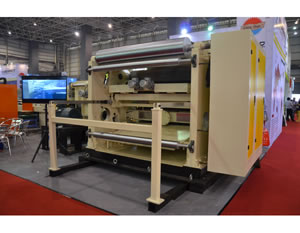

1. The corrugated cardboard production line is engineered with two sets of corrugating rollers, for corrugated cardboard shaping and preheating, respectively. The special design enables rapid mould replacement and convenient toothed roller maintenance.

2. For easy assembly and disassembly, the corrugating section is separated from the glue feeding section.

3. The vacuum sucking structure makes for optimal shaping performance of the single facer.

4. This single sided corrugated cardboard machine uses auto circulating glue supply. The glue feeding quantity can be adjusted and displayed digitally.

5. Safe and convenient, the pressure for rolling and gluing is hydraulically controlled, and the glue feeding and restoration of the cardboard making equipment are pneumatically controlled.

6. In addition to the independent driving box and oil bath lubrication, the connection of the cardan shaft and the machine body is conducive to the stable operation of the product.

7. Made of first class 48CrMo alloy steel, the corrugating roller is processed with middle frequency induction hardening technology with the hardness up to HRC55-58. The surface is grinded and chrome plated for extended service life.

8.Controlled by PLC system, this machine employs touch screen to display the operating parameters, realizing high level of man-machine conversation.

9. The single facer has two sets of glue feeding system and two sets of corrugating system, sharing the pressure roll together.

10. The designed speed of the full automatic single facer reaches up to 180 meters per minute.

| Lower Corrugating Roller Dia. | 320mm |

| Upper Corrugating Roller Dia. | 320mm |

| Pressure Roll | Made of #45 quenched seamless steel tube, with the diameter of 340mm |

| Glue Feeding Roller | Diameter: 240mm, material: #45 seamless steel tube processed with special engraved design and chromeplate |

| Preheat Roll | 20G steel tube with the diameter of 350mm from Baogang Group. |

Raw Materials

Side panels and pedestal: HT200 graphitic cast iron from Hebei

Pedestal for transmission section: box iron from Tangshan

Customers are welcomed to contact us for more details about the single facer.