This product has been discontinued and removed from our shelves.

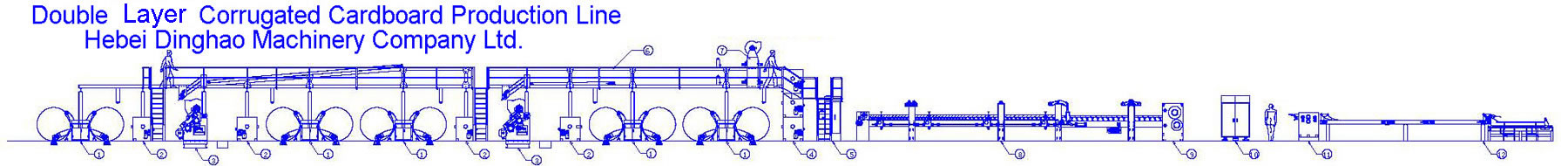

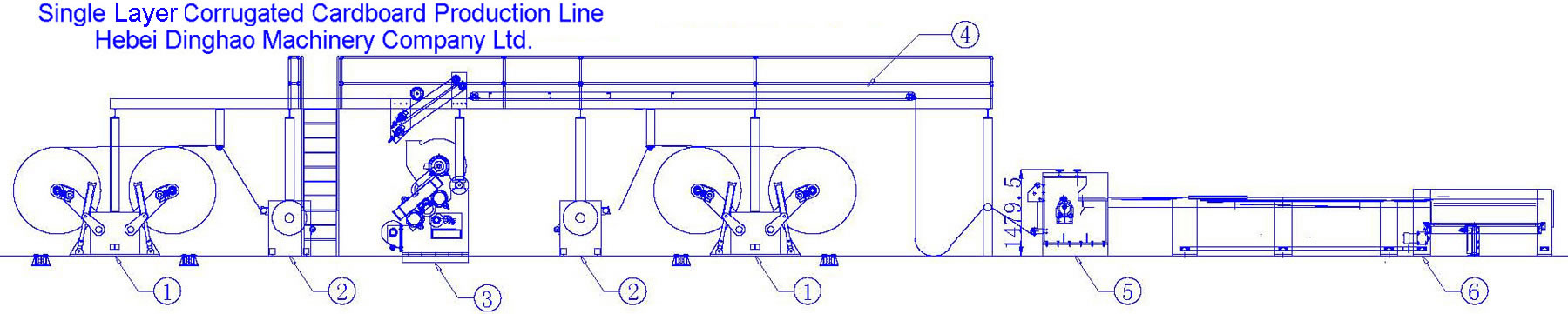

The SF-CW80 single facer is a preferred choice for customers demanding general production speed, as well as better economy and practicality. It can be assembled with reference to speed and flute size required by customers. The position of this product in the WJ computer high speed corrugated cardboard production line is shown in the diagram ③ and that in the HS high speed corrugated cardboard single sheet production line is represented in diagram ③.

Characteristics

1. The single facer utilizes domestically advanced inner absorption technology and corrugated roller with ring-shaped crescent slot. This guarantees low energy consumption, excellent air suction effect, good corrugated shape as well as high strength.

The single sided cardboard made by this product has a flat and exquisite appearance while being free from ring-shaped score common to the cover absorption type and leading claw type single facers. The production is simple and convenient. The corrugated paper is absorbed to the middle corrugated roller via the roller bore by the fan. In this way, a negative pressure zone is formed within 180°of the middle corrugated roller and the fluted rolling is achieved. The crescent-shaped air suction slot of the lower corrugated roller is not more than 1.6mm in width, making the single-faced corrugated cardboard free from stripe traces.

2. The reduction gearbox is lubricated by being dipped into the oil. It adopts the closed gear drive for vibration reduction.

3. This machine uses auto circulating glue supply, pneumatic glue coating and resetting, supplying good buffering effects.

4. The glue coating area is electrically adjusted and the gluing part runs independently when the single facer stops working so as to prevent glue from being dried up.

5. The glue feeding roller surface is specially treated with netlike and engraved decorations as well as chrome plating.

6. Both upper and lower corrugated rollers are fabricated from 48CrMo optimum quality alloy steel. With the heat treatment, their hardness ranges from HRC58 to 62°. Surfaces are grinded and chrome plated.

7. The effective operation breadth is between 2200mm and 1400mm. The production speed is 60m/min.

8. This product uses the gear and chain for transmission.

Structural Drawing of HS High Speed Corrugated Cardboard Single Sheet Production Line

1. Mill Roll Stand

2. Corrugated Cardboard Preheater

3. Single Facer

4. Feeding Overbridge Conveyor

5. Stacking Machine