The high speed automatic flute laminator is specially offered for laminating the color surface paper to the corrugated cardboard. The cardboard laminated has smooth and attractive appearance, and low rejection rate. Our flute laminating machine is widely used for manufacturing packing material for the product such as food, liquor, household appliances, textile, etc.

Features| Model | | | |

| Max. Sheet Size (W×L) | 1300×1000mm | 1450×1100mm | 1600×1200mm |

| Min. Sheet Size (W×L) | 500×440mm | 500×440mm | 500×440mm |

| Thickness of Surface Paper | 200-800g/m2 | 200-800g/m2 | 200-800g/m2 |

| Thickness of Backing Paper | 0-9mm | 0-9mm | 0-9mm |

| Max. Speed | 11000pcs/hr (Based on paper quality) | 11000pcs/hr (Based on paper quality) | 11000pcs/hr (Based on paper quality) |

| Laminating Accuracy (Front lay) | ±1.5m/m | ±1.5m/m | ±1.5m/m |

| Machine Weight | 6000kg | 6250kg | 6500kg |

| Total Length | 10.7m | 10.8m | 10.9m |

| Operation Space | 3×13.5m | 3.1×13.5m | 3.2×13.5m |

| Power | 380V 3~ (15hp) | 380V 3~(15hp) | 380V 3~(15hp) |

Surface paper feeder: feeding paper from 200 to 800gsm

Backing paper feeder: feeding corrugated cardboard with the thickness from 0 to 9mm

Conveyor: the conveyor is employed to press the laminated cardboard and deliver it to the cardboard collecting section.

Glue feeding unit: responsible for gelatinizing the cardboard

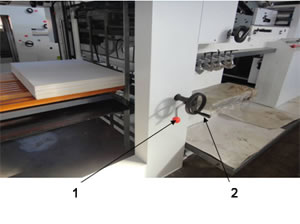

1.Upper paper feeder

2. Lower paper feeder

3. Front lay laminating device

4. Pressing and cardboard collecting unit

1. The corrugated cardboard laminator adopts high speed paper feeding device purchased from well-known supplier in China. In addition to the wide applicability, the simple operation and the convenient maintenance of the feeding device make this high speed automatic flute laminator quite popular.

A. The maximum designed speed of the paper feeding device reaches up to 16000 pieces per hours, and the maximum speed of this packing material production line is 11000 pieces per hour.

B. Smartly designed, the double-layer rubber for paper separating and the single-layer rubber for paper conveying effectively avoid the occurrence of multiple paper conveying.

C. High speed and stable operation, low noise.

2. The surface paper conveying device of the high speed automatic flute laminator employs overlapped paper feeding mode. Compared with interval conveying of single paper, the paper feeding speed is reduced, ensuring smooth paper conveying. In addition, paper scraping can be eliminated. This design is particularly suitable for the paper with unsmoothed surface, because the upper paper helps flatten the paper below, avoiding the shutdown caused by paper warping.

3. An auxiliary surface paper feeding mechanism is engineered for the high speed automatic flute laminator to realize continuous paper feeding during operation. This design is conducive to the high working efficiency of our product.

4. Lay Regulation

A. The special design of the surface paper feeding device is conducive to the convenient positioning of the side lay. This high speed automatic flute laminator comes with the hand wheel and hand lever for overall regulation and fine regulation based on the breadth of the surface paper, respectively.

1. Hand lever for side lay regulation

2. Hand wheel for overall regulation on the breadth of the surface paper

B. The positioning of the corrugated cardboard can be adjusted through the operation on the hand wheel of the high speed automatic flute laminator according to the cardboard size. User can obtain the required size easily based on the figure indication on the hand wheel.

C. A side lay is installed on the operating unit and the transmission part of the high speed automatic flute laminator. It is specially offered for easy regulation before lamination, resulting in the maximum accuracy of the side edge.

In case precise adjustment is required after the lamination of the surface paper and the backing paper, this hand wheel can be used for regulation. The surface paper will be horizontally moved by 1.75mm for each rotation.

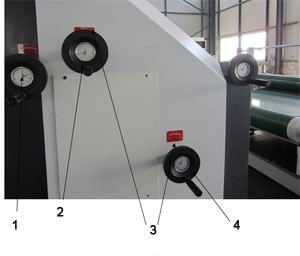

5. For the production with different surface paper and backing paper, the pressure and glue amount adjustment can be simply completed through the operation on the hand wheel of the high speed automatic flute laminator. Based on the model and thickness of the corrugated cardboard, user can directly turn the hand wheel to the relevant figure. This design saves much time for the users.

1. Dial plate

2. Hand wheel for glue quantity regulation

3. Direction indication

4. Hand wheel for paper thickness regulation

6. Our high speed automatic flute laminator uses imported level controller for the automatic glue feeding system. A signal will be sent to the paper feeding device in case there is little glue left in the barrel. The level controller can effectively avoid paper waste.

7. A protection device is installed at the pressing conveyor for the paper from the main press roller, to avoid waste cause by paper disorder.

8. For the gelatinizing device, there is a set of special roller for wetting and cleaning the dirt of the backing paper. Through the adjustment on the water amount, cardboard with optimal smoothness can be obtained.

9. The anilox roller for gelatinizing of the high speed automatic flute laminator is manufactured with special processing technology featuring glue saving. Taking white glue for example, the minimum amount of glue applied is about 30g/m2, 5g to 10g less than that of other rollers. The special processing technology is capable of avoiding paper rolling.

10. Laying great emphasis on the quality of the machine, we particularly introduce bearings from NSK for the key parts and the bearings from the well-known C&U Group in China for the non-critical parts of the high speed automatic flute laminator. We take every last detail into consideration during the assembly of the bearing. The dedicated personnel will record the assembly conditions, carefully.

Customers are welcomed to contact us for more information related to the technical parameters.